Optimize Track Life: Adjust Mini Excavator Rubber Tracks with Precision

Table of Contents

- Introduction

- Importance of Proper Track Adjustment

- Finding the Proper Track Tension

- Track Tension Measurement Chart

- Track Tension Adjustment Tool

- Precautions Before Adjusting the Track

- Machine Support and Hydraulic Trust

- Track Tension Grease Fitting

- Steps to Properly Adjust the Track

- Loosening the Track Tensioner Plate

- Applying Grease for Track Tension

- Monitoring Track Tension Gap

- Loosening the Track Tensioner

- Proper Track Sound and Visual Inspection

- The Consequences of Improper Track Tension

- Components at Risk

- Damages and Premature Wear

- Conclusion

Proper Track Adjustment: Prolonging Track Life and Improving Operating Quality

In the construction industry, maximizing the lifespan of machinery is crucial for maintaining profitability. One essential aspect of equipment maintenance is properly adjusting the track tension. This article will guide you through the process of adjusting track tension correctly. We will begin by understanding the significance of proper track adjustment and then delve into practical steps to achieve optimal results.

1. Introduction

As a business owner or operator, it is vital to prioritize the maintenance of your machinery. Adjusting the track tension plays a pivotal role in prolonging the track's life, enhancing operating quality, and avoiding costly damages. This article will provide you with comprehensive insights and step-by-step instructions on how to achieve the proper track tension.

2. Importance of Proper Track Adjustment

Proper track adjustment is critical for several reasons. It ensures optimal performance, reduces wear and tear on essential components, and prevents potential hazards. By maintaining the right track tension, you can extend the lifespan of your track and enhance the overall operational efficiency of your machinery. Let us now explore how to find the appropriate track tension measurement.

3. Finding the Proper Track Tension

3.1 Track Tension Measurement Chart

To determine the correct track tension, refer to the operator manual of your machine. In the manual, you will find a chart that illustrates how to measure the track and provides instructions for adjustment. According to the chart, the normal sag between the top of the pleat and the bottom of the roller should be between 10 and 20 mm.

3.2 Track Tension Adjustment Tool

To simplify the track tension adjustment process, a custom tool can be used. This tool creates a maximum 20 mm gap, which aligns with the high-end adjustment range recommended by the manual. The tool ensures precision and accuracy during the adjustment process, resulting in optimal track tension.

4. Precautions Before Adjusting the Track

Before adjusting the track tension, it is crucial to take certain precautions to ensure your safety and the proper functioning of the machine.

4.1 Machine Support and Hydraulic Trust

Make sure the machine is adequately supported. While hydraulic systems provide support, it is essential not to solely rely on them. Keep your hands and feet away from underneath the track to prevent accidents in case of hydraulic failure.

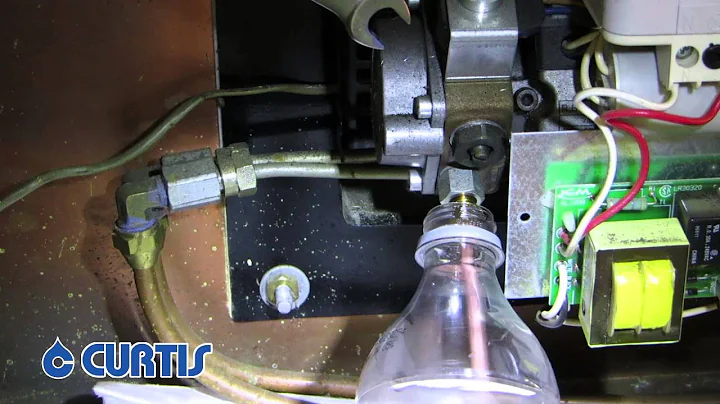

4.2 Track Tension Grease Fitting

Loosen the plate covering the track tension grease fitting. Slide the plate back to reveal the track tensioner. It is important to note that only a small amount of grease is required for the adjustment process. Be mindful of the quantity to avoid over-greasing.

5. Steps to Properly Adjust the Track

5.1 Loosening the Track Tensioner Plate

Begin by loosening the track tensioner plate using a suitable tool. This step will grant access to the track tensioner mechanism for adjustment.

5.2 Applying Grease for Track Tension

Apply a minimal amount of grease to facilitate the track tension adjustment. Slowly turn the track tensioner to ensure a controlled and precise adjustment. Observe the bouncing movement of the track, indicating the gradual increase in tension.

5.3 Monitoring Track Tension Gap

Continue adjusting until the gap between the top of the pleat and the bottom of the roller reaches the desired 20 mm measurement. This gap ensures the proper track tension, leading to smooth and noise-free operation.

6. Loosening the Track Tensioner

To release the tensioner and loosen the track, loosen the jam nut using a 19 mm tool. This will allow the grease and tensioner in the track to fall.

7. Proper Track Sound and Visual Inspection

A properly adjusted track will produce a smooth sound without any popping or grinding noise. Regularly inspect the track tension to ensure it remains within the recommended range. Neglecting track tension can result in severe damages and premature wear of critical components.

8. The Consequences of Improper Track Tension

8.1 Components at Risk

Inappropriate track tension can lead to significant damages to various machine components. Key elements vulnerable to wear and tear include the idler, segments, top and bottom rollers, and the track itself.

8.2 Damages and Premature Wear

Excessive track tension can cause the track to snap or continuously push out, damaging both the rubber and steel components. Additionally, it can result in accelerated wear of the bearings inside the idlers, upper, and lower rollers. These consequences can be costly and impact the efficiency of your equipment.

9. Conclusion

Maintaining the proper track tension is a key factor in optimizing the performance and longevity of your machinery. By following the guidelines and precautions outlined in this article, you can ensure the efficient operation of your track and prevent unnecessary damages. Regular inspection and adjustment of track tension will contribute to the overall success of your business, reducing maintenance costs and enhancing productivity. Take the time to adjust your track properly, and you will reap the benefits in the long run.

Highlights:

- Proper track adjustment is crucial for prolonging track life and optimizing operating quality.

- Use the operator manual's track tension measurement chart and a track tension adjustment tool for accuracy.

- Ensure machine support and use caution around hydraulic systems.

- Slowly adjust the track tension while monitoring the gap between the pleat and the roller.

- Improper track tension can lead to component damages and premature wear.

- Regular inspections and maintenance are essential for long-term efficiency and cost savings.

FAQ

Q: What happens if the track tension is too tight?

A: Excessive track tension can result in damage to various machine components, including the idler, segments, rollers, and track itself. It can also cause premature wear of bearings and lead to costly repairs.

Q: How often should I adjust the track tension?

A: Regular track tension inspections are recommended, especially before extensive use or after significant operation time. Conduct inspections at least once a month or as per the machine's manufacturer recommendations.

Q: Can improper track tension affect machine productivity?

A: Yes, improper track tension can negatively impact machine productivity. It can cause unnecessary stress on components, leading to reduced efficiency, increased fuel consumption, and potential breakdowns.

Q: Are there any signs to indicate that the track tension needs adjustment?

A: Yes, signs of improper track tension include excessive track vibration, abnormal noises during operation, increased track wear, and poor machine performance. Regular checks can help identify these indicators.

Q: Is track tension adjustment a difficult task?

A: With the proper tools, precautions, and understanding of the process, adjusting track tension is relatively straightforward. However, it is essential to follow the manufacturer's guidelines and consult professionals if needed.