Build Your Own Electric Calcium Chloride Spray Unit

Table of Contents:

- Introduction

- The Need for Electric Calcium Chloride Spray Units

- Advantages of Liquid Calcium Chloride

- Building the 12 Volt Electric Calcium Chloride Spray Unit

- Materials and Tools Required

- Assembling the Spray Bar

- Connecting the Cam Lock Fittings

- Mounting the Pump and Hardware

- How the Electric Calcium Chloride Spray Unit Works

- Using the 12 Volt Electric Calcium Chloride Spray Unit

- Operating Instructions

- Maintenance Tips

- Pros and Cons of Electric Calcium Chloride Spray Units

- Comparing Rock Salt and Liquid Calcium Chloride

- Advantages of Rock Salt

- Advantages of Liquid Calcium Chloride

- Disadvantages of Rock Salt

- Disadvantages of Liquid Calcium Chloride

- Conclusion

- Resources

💡 Highlights:

- Transitioning from rock salt to liquid calcium chloride for increased stability in pricing and reduced reliance on marquee-heavy products.

- Building 12 volt electric calcium chloride spray units for efficient and versatile use in pretreatment and post-treatment.

- Using cam lock fittings and spray bar for easy installation and maintenance.

- The advantages and disadvantages of rock salt and liquid calcium chloride.

Building an Effective 12 Volt Electric Calcium Chloride Spray Unit

With the rising demand for more stable pricing and reduced reliance on rock salt, many individuals and businesses are turning to liquid calcium chloride as an alternative for de-icing and anti-icing purposes. In this article, we will guide you through the step-by-step process of building your own 12 volt electric calcium chloride spray unit, exploring its advantages, and comparing it to the traditional use of rock salt.

1. Introduction

De-icing and anti-icing techniques have evolved over the years, and one of the popular alternatives to traditional rock salt is liquid calcium chloride. This versatile substance offers increased stability in pricing and proves to be more effective in extreme weather conditions. In order to harness the benefits of liquid calcium chloride, we will show you how to build your own 12 volt electric calcium chloride spray unit.

2. The Need for Electric Calcium Chloride Spray Units

The need for electric calcium chloride spray units arises from the desire to transition from traditional rock salt to a more reliable and cost-effective solution. By using these units, you can effectively pretreat and post-treat surfaces to prevent the formation of ice, provide traction, and reduce accidents and injuries on roads, parking lots, sidewalks, and more.

3. Advantages of Liquid Calcium Chloride

Liquid calcium chloride offers several advantages over rock salt. Firstly, it has a lower freezing point, allowing it to melt ice at much lower temperatures. This makes it highly effective in extreme weather conditions. Additionally, liquid calcium chloride is less corrosive than rock salt, reducing damage to infrastructure and vehicles. It is also more environmentally friendly and poses fewer risks to humans and animals.

4. Building the 12 Volt Electric Calcium Chloride Spray Unit

4.1 Materials and Tools Required

To build your own 12 volt electric calcium chloride spray unit, you will need the following materials and tools:

- 2x2 tubing and angle iron

- Threaded fittings and caps

- Cam lock system

- Pump with a filter

- U-bolts

- Steel plate

- Paint

4.2 Assembling the Spray Bar

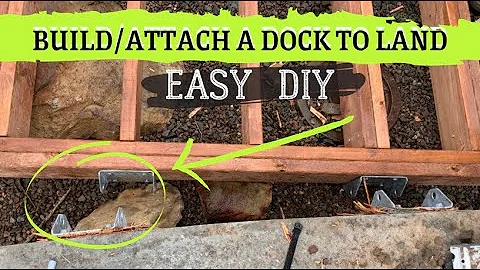

The spray bar is an essential component of the electric calcium chloride spray unit. It is typically constructed using 2x2 tubing and angle iron. By welding these pieces together, you can create a sturdy and durable spray bar that can easily slide into a hitch. To ensure the full length of the boom is covered, it is recommended to use PVC pipe instead of smaller setups. This helps prevent brittleness and breakage in cold temperatures.

4.3 Connecting the Cam Lock Fittings

To facilitate easy assembly and maintenance, it is advisable to use cam lock fittings at the ends of the spray bar. These fittings allow for quick disconnection and flushing of the system if any debris accumulates. Additionally, a cam lock system can be implemented for the center section of the spray bar, enabling swift detachment when necessary.

4.4 Mounting the Pump and Hardware

To achieve a professional and secure setup, mounting the pump and hardware onto a board or steel plate is recommended. This ensures stability and reduces the risk of damage during operation. While some may opt for zip ties, attaching the components to a solid surface gives a more polished appearance.

5. How the Electric Calcium Chloride Spray Unit Works

The electric calcium chloride spray unit operates using a 12-volt pump that connects to a spray handle and a quarter-turn valve. The pump draws liquid calcium chloride from a tank through a filter, ensuring debris is removed before dispersion. The spray handle allows for the precise application of liquid calcium chloride on surfaces such as parking lots, sidewalks, and roads. The unit provides the option to shut off the spray bar and exclusively use the wand, offering versatility in treating different areas.

6. Using the 12 Volt Electric Calcium Chloride Spray Unit

6.1 Operating Instructions

Using the 12 volt electric calcium chloride spray unit is relatively simple. Plug the wire harness into the cigarette lighter socket for power. Utilize the on-off switch to control the flow of liquid calcium chloride. For best results, follow the recommended application rates and spray patterns provided by the manufacturer.

6.2 Maintenance Tips

Regular maintenance is crucial to ensure the longevity and efficiency of the electric calcium chloride spray unit. This includes checking the filter for debris, cleaning the spray bar and wand after each use, and inspecting the connections for any signs of wear or leakage. It is also important to store the unit properly during the off-season and to follow safety guidelines when handling liquid calcium chloride.

7. Pros and Cons of Electric Calcium Chloride Spray Units

Electric calcium chloride spray units offer numerous advantages, such as reduced reliance on rock salt, increased stability in pricing, and quieter operation compared to gas units. However, it is important to consider some potential drawbacks, including limited pump capacity and reduced pressure when using both the spray bar and wand simultaneously. Overall, the benefits of electric calcium chloride spray units outweigh the limitations for most applications.

8. Comparing Rock Salt and Liquid Calcium Chloride

8.1 Advantages of Rock Salt

- Relatively low cost and widespread availability

- Ability to provide traction on icy surfaces

- Effective in moderate winter conditions

8.2 Advantages of Liquid Calcium Chloride

- Lower freezing point, making it effective in extreme temperatures

- Reduced corrosion and damage to infrastructure and vehicles

- Environmentally friendly and less harmful to humans and animals

8.3 Disadvantages of Rock Salt

- Price volatility due to market conditions

- The potential for environmental damage and harm to vegetation

- Limited effectiveness in very low temperatures

8.4 Disadvantages of Liquid Calcium Chloride

- Higher initial investment compared to rock salt

- Limited pump capacity and reduced pressure when using multiple outlets simultaneously

- The need for regular maintenance and proper storage

9. Conclusion

Building a 12 volt electric calcium chloride spray unit can revolutionize your de-icing and anti-icing efforts. By taking advantage of the benefits of liquid calcium chloride, such as increased stability in pricing and reduced reliance on rock salt, you can ensure safer surfaces during winter months. Whether you choose to build your own unit or purchase one, considering the advantages and disadvantages of different de-icing methods is crucial in making an informed decision.

10. Resources

FAQs

Q: Can the 12 volt electric calcium chloride spray unit be used for residential purposes?

A: Yes, the unit can be used for both residential and commercial applications. It is particularly useful for treating sidewalks, driveways, and small parking areas.

Q: How often does the filter need to be cleaned?

A: It is recommended to check and clean the filter after each use to prevent debris from clogging the system. Regular maintenance ensures optimal performance.

Q: Is it possible to switch back to rock salt if needed?

A: Yes, switching back to rock salt is possible, especially when budget constraints or other factors arise. However, liquid calcium chloride offers various advantages that make it a popular choice for de-icing and anti-icing purposes.

Q: Can the spray unit be used with other de-icing solutions?

A: While the unit is primarily designed for liquid calcium chloride, it can also be used with other de-icing solutions. However, it is important to consider the compatibility and effects of different solutions on surfaces and the environment.

Q: Can the pump and fittings be upgraded for higher capacity and pressure?

A: Yes, it is possible to upgrade the pump and fittings to achieve higher capacity and pressure. This may require additional research and investment, but it can enhance the performance of the spray unit for larger-scale applications.