Efficient Carbonation System for Beverage Production - Introducing Easio 5 Barrel

Table of Contents

- Introduction

- The Easio 5 Barrel Carbonation System

- Components of the System

- 3.1 Humi Control Panel

- 3.2 Syrup Tank

- 3.3 Water Tank

- 3.4 Mixing Tank

- Operation of the System

- 4.1 Adding Water and Syrup

- 4.2 Removing Oxygen from the Water

- 4.3 Pumping the Water and Syrup

- 4.4 Adjusting the Flow Rate

- 4.5 Mixing the Water and Syrup

- 4.6 Testing the Ratio

- 4.7 Carbonation Process

- 4.8 Co2 Connection

- Filling Line and Production

- Easy-to-use Features

- Quality Components

- Conclusion

🔍 Introduction

Are you looking for an efficient carbonation system for your beverage production? Look no further as we introduce the Easio 5 Barrel Carbonation System. In this article, we will discuss the various components of the system and how it operates to create carbonated beverages. Let's dive in!

🏭 The Easio 5 Barrel Carbonation System

The Easio 5 Barrel Carbonation System is a top-of-the-line solution for carbonating beverages. It offers precise control and high efficiency, making it ideal for commercial use. With its advanced features and user-friendly interface, this system ensures excellent carbonation results every time.

🔧 Components of the System

To understand the workings of the Easio 5 Barrel Carbonation System, let's take a closer look at its key components.

3.1 Humi Control Panel

The Humi Control Panel is the heart of the system, providing easy control and monitoring of each unit. Using the intuitive touch screen interface, customers can effortlessly manage all the functions of the system.

3.2 Syrup Tank

The syrup tank is used for storing the syrup, one of the key ingredients in the carbonation process. It ensures a steady supply of syrup for the production line.

3.3 Water Tank

The water tank holds the water required for the carbonation process. It is connected to the vacuum pump and plays a crucial role in removing oxygen from the water.

3.4 Mixing Tank

The mixing tank is where the water and syrup are combined to create the beverage mixture. It has a sample valve for testing the ratio and adjustable flow valves for precise control over the flow rate of the water and syrup.

🔧 Operation of the System

Now that we are familiar with the components, let's explore how the Easio 5 Barrel Carbonation System operates.

4.1 Adding Water and Syrup

To initiate the carbonation process, water needs to be added to the water tank. The water type vacuum pump inside the tank requires a sufficient amount of water to work effectively. It is essential to ensure the water level is adequate; otherwise, the pump won't function correctly.

4.2 Removing Oxygen from the Water

The system includes a vacuum tank designed to eliminate oxygen from the water, resulting in low levels of dissolved oxygen. This tank works in conjunction with the vacuum pump, which creates pressure inside the water tank. The pressure is displayed on a pressure gauge, and the oxygen is effectively removed.

4.3 Pumping the Water and Syrup

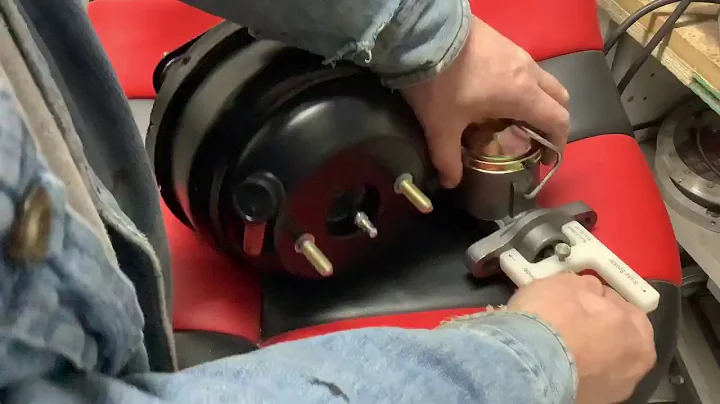

After the oxygen is removed, the water and syrup flow through the respective pipes. The syrup is connected through the syrup entry, and the water flows through the water entry. The connections are made using chi-clamp quick connections, ensuring a secure and efficient flow.

4.4 Adjusting the Flow Rate

The flow rate of the water and syrup can be adjusted using the flow valves located in the mixing tank. This allows for precise control of the ratio between the two ingredients. By simply adjusting the flow valves, customers can fine-tune the mixture according to their desired specifications.

4.5 Mixing the Water and Syrup

Once the water and syrup are properly flowing, they mix together in the mixing tank. The mixture starts from the bottom of the tank and gradually moves upward, ensuring thorough blending of the ingredients. The mixing process is continuously ongoing during production.

4.6 Testing the Ratio

To ensure the correct ratio of water and syrup in the mixture, customers can test it using the valve located on the mixing tank. This allows for real-time checking of the ratio, ensuring that the product meets the desired specifications.

4.7 Carbonation Process

After the mixing process, the mixture is pumped through a heat exchanger. This heats the product to a precise temperature of around 32 degrees, ensuring optimal carbonation. The carbonated mixture then proceeds to the carbonation tank.

4.8 CO2 Connection

A CO2 connection is made to the system to facilitate the carbonation process. The flow of CO2 is adjusted using a flow meter and can be monitored using a gauge. The carbonation level can be precisely controlled based on the desired pressure and flow of CO2.

🏭 Filling Line and Production

Once the carbonation process is complete, the carbonated beverage from the carbonation tank is ready for the filling line. The connection from the tank ensures a smooth transition to the filling machine, allowing for continuous production. The Easio 5 Barrel Carbonation System provides a seamless and efficient production line for carbonated beverages.

🔧 Easy-to-use Features

The Easio 5 Barrel Carbonation System is designed for user convenience. With its automatic running feature, users can simply activate the system and let it do the work. The valves and pumps operate based on the predetermined settings and the level in the tanks. This simplicity ensures hassle-free operation, making it suitable for both experienced and novice users.

💎 Quality Components

The Easio 5 Barrel Carbonation System is built using high-quality components. The electrical parts, such as the Schneider and Mitsubishi components, are sourced from renowned brands in the international market. This guarantees the longevity and reliability of the system, reducing maintenance and downtime.

👍 Conclusion

In conclusion, the Easio 5 Barrel Carbonation System is a reliable and efficient solution for producing carbonated beverages. Its easy-to-use features, precise control, and high-quality components make it a top choice for commercial beverage production. Invest in the Easio 5 Barrel Carbonation System and experience optimum results in your carbonated beverage production process.

FAQ

Q: Can I adjust the ratio of water and syrup in the mixture?

A: Yes, the Easio 5 Barrel Carbonation System allows for easy adjustment of the flow rate to control the ratio according to your requirements.

Q: How does the system ensure proper carbonation?

A: The system utilizes a heat exchanger to heat the mixture to a precise temperature of around 32 degrees before it is pumped to the carbonation tank, ensuring ideal carbonation levels.

Q: Are the electrical parts of the system reliable?

A: Yes, the system employs electrical components from trusted brands like Schneider and Mitsubishi, guaranteeing durability and dependability.

Q: Is the system easy to operate?

A: Absolutely! The Easio 5 Barrel Carbonation System features an intuitive Humi Control Panel, making it user-friendly and simple to manage.