Maximize Brass Lifespan: Proper Annealing Techniques

Table of Contents:

- Introduction

- Understanding Cartridge Case Annealing

- The Importance of Annealing

- The Traditional Method of Annealing

- The Torch Method of Annealing

- Steps to Anneal Cartridge Cases Using a Torch

- Safety Precautions

- Benefits of Cartridge Case Annealing

- Extending the Life of Brass

- Conclusion

Understanding Cartridge Case Annealing

Cartridge case annealing, also known as stress-relieving, is a critical process in the reloading of ammunition. It involves heating the brass case to a specific temperature and then rapidly cooling it to relieve the built-up stresses from firing and sizing. This process helps improve the longevity and performance of the cartridge case.

The Importance of Annealing

Annealing is crucial because it helps maintain the desired hardness in different areas of the brass case. The case head needs to be hard to withstand pressure, while the neck and shoulder area should be softer to allow for expansion and effective chamber sealing. By annealing, shooters can ensure consistent performance and prevent case failures, such as splitting or collapsing.

The Traditional Method of Annealing

The traditional method of annealing involves standing the cartridge cases in a pan of water and heating them unevenly with a torch. However, this method has drawbacks as it often results in an uneven distribution of heat and can lead to a dead-soft state in the case, making it prone to shoulder collapse during reloading.

The Torch Method of Annealing

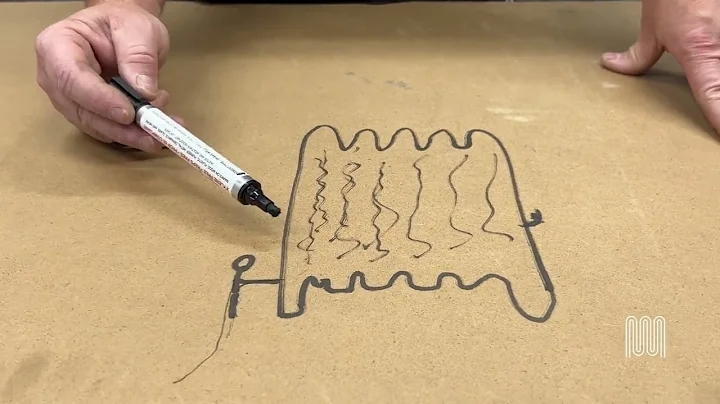

An alternative method that is gaining popularity among reloaders is using a torch to anneal the cartridge cases. This method provides more control over the heating process and ensures a more even heat distribution throughout the case.

Steps to Anneal Cartridge Cases Using a Torch

-

Clean the cartridge cases thoroughly to remove any contaminants that may hinder the annealing process.

-

Set up a well-ventilated workspace with a fire-resistant surface and have a container of water nearby for rapid cooling.

-

Use a propane-powered torch to heat the brass case. Hold the case with your fingers and rotate it in the flame.

-

Observe the color change in the brass case. The desired temperature range for annealing is indicated by a distinct color change, typically a shade of blue or purple.

-

Once the desired color change is achieved, quickly immerse the case in the water to cool it rapidly. Ensure the entire case is submerged for an even cooling effect.

-

Repeat the process for all the cartridge cases, taking breaks to avoid overheating the torch or your fingers.

Safety Precautions

-

Always wear appropriate protective gear, such as gloves and safety glasses, when handling the torch and hot brass.

-

Work in a well-ventilated area to avoid inhaling fumes generated during the annealing process.

-

Keep a fire extinguisher or a bucket of sand nearby in case of accidents or flare-ups.

-

Follow all safety guidelines provided by the torch manufacturer.

Benefits of Cartridge Case Annealing

-

Extended Brass Life: Annealing cartridge cases regularly can significantly extend their lifespan, allowing reloaders to reuse them for multiple firing and resizing cycles.

-

Reduced Case Failures: Annealing helps prevent case failures such as splitting, which can occur when brass becomes too brittle due to work-hardening.

-

Improved Chamber Sealing: The softer neck and shoulder area resulting from annealing allow the cartridge case to expand properly, ensuring effective chamber sealing and preventing blowback.

-

Cost Savings: Brass is the most expensive component of reloaded ammunition. By preserving and reusing brass through annealing, shooters can save money in the long run.

Conclusion

Cartridge case annealing is a crucial process for reloaders who want to maximize the lifespan of their brass and ensure consistent performance. By following proper annealing techniques and taking necessary safety precautions, shooters can enjoy the benefits of extended brass life, reduced case failures, and improved chamber sealing. So, invest some time in annealing your cartridge cases, and you'll reap the rewards in the form of reliable and cost-effective ammunition.

Highlights:

- Cartridge case annealing is the process of heating and rapidly cooling brass cases to relieve stress and improve their lifespan.

- Traditional annealing methods often result in uneven heat distribution and a dead-soft state in the case.

- The torch method of annealing provides more control and ensures even heat distribution throughout the case.

- Steps to anneal cartridge cases using a torch involve cleaning, heating, observing color change, and rapid cooling.

- Safety precautions such as wearing protective gear and working in a well-ventilated area are essential during annealing.

- Benefits of annealing include extended brass life, reduced case failures, improved chamber sealing, and cost savings.

FAQ:

Q: How often should I anneal cartridge cases?

A: It is recommended to anneal cartridge cases every five to six reloading cycles to maintain their longevity and prevent failures.

Q: Can I reuse brass without annealing?

A: Yes, you can reuse brass without annealing, but annealing greatly extends the life of the brass and improves its performance.

Q: Is torch annealing dangerous?

A: Torch annealing can be dangerous if not done with proper safety precautions. It is important to wear protective gear and work in a well-ventilated area.

Q: Can I anneal cartridge cases with a different method?

A: Yes, there are other methods of annealing, such as using specialized annealing machines or induction annealing. However, the torch method described here is a cost-effective and accessible option for most reloaders.

Q: Can I anneal different calibers of cartridge cases using this method?

A: Yes, the torch method can be used for annealing cartridge cases of various calibers. The heating and cooling times may vary slightly depending on the size and thickness of the brass.

Resources: