Poudre noire sans soufre pour fusil antique

Table of Contents

- Introduction

- Importance of Sulfur in Antique Muzzle Loading Propellant

- Historical Significance

- Purpose of Sulfur

- Making Sulfur-Free Black Powder

- Composition and Ingredients

- Testing Results

- Performance Comparison in Muzzle Loader

- Performance Comparison in Cartridge

- The Role of Sulfur in Powder Cornification

- Vulcanization Process

- Effects on Grain Hardness

- Conclusion

- Additional Considerations for Sulfur-Free Black Powder

- FAQ

📜 Importance of Sulfur in Antique Muzzle Loading Propellant

Sulfur plays a vital role in the creation of antique muzzle loading propellant. Throughout history, obtaining sulfur for powder production has been a significant challenge, with armies and governments going to great lengths to acquire it. This article delves into the historical significance and purpose of sulfur, shedding light on its importance in the creation of antique muzzle loading propellant.

Historical Significance

In the 1500s, during the conflict between Cortes and the Aztecs in Mexico, the need for sulfur became apparent. The depleted powder supplies required an expedition to a volcano, where sulfur was retrieved for making propellant. This anecdote highlights the lengths commanders and armies would go to acquire this essential component.

Purpose of Sulfur

Sulfur serves two crucial purposes in antique muzzle loading propellant. Firstly, it lowers the ignition temperature, enabling the propellant to ignite more easily. Secondly, it acts as both an accelerator and a fuel, contributing to the burning process. By catching fire before the other components, like potassium nitrate and charcoal, sulfur ensures the propellant ignites efficiently.

🧪 Making Sulfur-Free Black Powder

Contrary to popular belief, it is possible to create sulfur-free black powder that can still function as antique muzzle loading propellant. This section explores the composition, ingredients, and testing results of sulfur-free black powder.

Composition and Ingredients

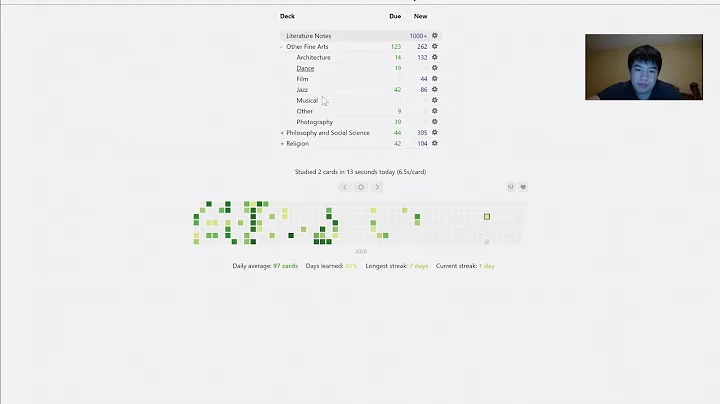

The sulfur-less black powder consists of a mixture comprising 70% potassium nitrate and 30% pacific willow charcoal. The ingredients are milled for 12 hours and subsequently compressed, corned, and granulated. This process ensures the powder's consistency and quality.

Testing Results

Open-air tests were conducted to evaluate the performance of the sulfur-free black powder. The initial test involved using the powder straight from the mill, and the results were promising. The subsequent test used the powder after compression and corning, demonstrating satisfactory performance and even a purple hue.

Performance Comparison in Muzzle Loader

To determine the sulfur-less black powder's efficacy in a muzzle loader, multiple shots were fired using a consistent charge of 50 grains of powder, a 20,000 patch, and a 440 round ball. The velocities achieved were analyzed to determine the powder's performance.

The results showed that the sulfur-free black powder produced velocities averaging 1103 feet per second, with a maximum spread of 51 feet per second. While not on par with other powders, it is sufficient for muzzle loader use, especially if the powder charge is increased by 50-100 grains to achieve higher velocities.

Performance Comparison in Cartridge

When dealing with limited case capacity, like in cartridges or revolvers such as the 1860 Army, the sulfur-free black powder's performance diminishes. Tests conducted with 25 grains of sulfur-free black powder in an 1860 Army revolver showed erratic velocities and wide variations.

The absence of sulfur in the powder affected the hardness of the grains during corning. This softer grain contributed to inconsistencies in compression, resulting in varying velocities. Comparatively, using 25 grains of Swiss 3f powder, designed to contain sulfur, yielded consistent and satisfactory performance.

🧪 The Role of Sulfur in Powder Cornification

The presence of sulfur during the corning process plays a crucial role in determining grain hardness and consistency. Vulcanization, caused by sulfur under pressure, hardens the powder grains, ensuring uniformity.

Vulcanization Process

When sulfur is present during the corning process, it vulcanizes the powder pucks, transforming them into hard, ceramic-like grains. These hardened grains maintain their integrity, even when broken into smaller pieces.

Effects on Grain Hardness

In the absence of sulfur, the resultant grains are noticeably softer. This softness compromises the consistency of compression, leading to variances in velocities when used in firearms like the 1860 Army revolver.

📝 Conclusion

While it is possible to create sulfur-free black powder for antique muzzle loading propellant, the performance may not be on par with powders containing sulfur. However, in times of necessity or unavailability, increasing the powder charge can help compensate for the lower velocities. It is essential to recognize the impact of sulfur on the cornification process, which directly affects grain hardness and uniformity.

💡 Additional Considerations for Sulfur-Free Black Powder

When using sulfur-free black powder, it is crucial to account for the limitations associated with its composition. Factors such as case capacity, compression consistency, and desired velocities should be considered when determining the suitability of sulfur-free black powder for specific applications.

❔ FAQ

Q: Can sulfur-free black powder be used in modern firearms?

A: No, sulfur-free black powder is not recommended for use in modern firearms due to its inconsistent performance and potential safety hazards.

Q: Is sulfur-free black powder legal to manufacture and possess?

A: Regulations regarding black powder may vary by jurisdiction. It is crucial to consult local laws and regulations before manufacturing or possessing sulfur-free black powder.

Q: Can sulfur-free black powder be used as a substitute for modern smokeless powders?

A: No, sulfur-free black powder is not a suitable substitute for modern smokeless powders. It is specifically intended for antique muzzle loading propellant purposes.

Q: Are there any other alternatives to sulfur-free black powder for antique muzzle loading propellant?

A: While sulfur is a commonly used component in antique muzzle loading propellant, there are other variations and recipes available that achieve similar results. It is recommended to explore different compositions and consult experienced black powder enthusiasts for alternative options.

Q: Are there any safety precautions when working with sulfur-free black powder?

A: The same safety precautions applied to regular black powder should also be followed when working with sulfur-free black powder. These include proper storage, handling, and safe usage practices to prevent accidents and injury.

Resources

WHY YOU SHOULD CHOOSE Proseoai

WHY YOU SHOULD CHOOSE Proseoai