Effective Solenoid Testing with a Volt Meter for Sprinkler Systems

Table of Contents

- Introduction

- Testing a Solenoid Using a Volt Meter

- Signs of a Bad Solenoid

- The Importance of Testing Solenoids

- Steps to Test a Solenoid with a Volt Meter

- Understanding Resistance in Solenoids

- Testing a Good Solenoid

- Proper Disposal of Bad Solenoids

- Tips for Irrigators

- Conclusion

Testing a Solenoid Using a Volt Meter

Solenoids play a crucial role in the function of sprinkler systems. They control the flow of water to different zones in the system, allowing for efficient irrigation. However, solenoids can become faulty over time, leading to issues with the system's functionality. Testing solenoids is essential to identify any problems and determine whether they need to be replaced. In this article, we will discuss how to test a solenoid using a volt meter, providing you with a step-by-step guide on the process.

Signs of a Bad Solenoid

Before we dive into the testing method, it's important to understand the signs that indicate a solenoid may be faulty. One of the common indications is a zone that is not working despite having water supply. This could be a result of a damaged solenoid or a wire issue. Another telltale sign is a hot solenoid, which could be due to internal malfunctions. By recognizing these signs, you can determine if testing the solenoid is necessary.

The Importance of Testing Solenoids

Testing solenoids is crucial for maintaining the functionality of a sprinkler system. It helps to accurately diagnose the problem and prevent unnecessary troubleshooting or repairs. By identifying a faulty solenoid, you can ensure that water flow is properly controlled within the system. This not only saves water but also prevents damage to the landscape caused by under or over-irrigation. Regularly testing solenoids can help to prevent costly repairs and ensure the longevity of your irrigation system.

Steps to Test a Solenoid with a Volt Meter

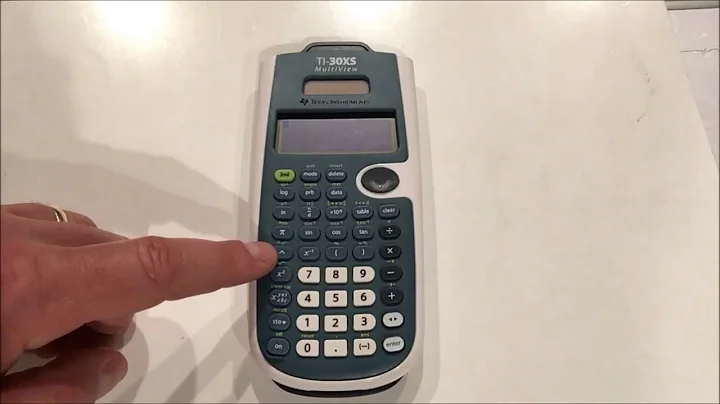

- Gather the necessary tools: a volt meter with ohm settings and a solenoid to be tested.

- Strip back a small section of wire from the solenoid for testing.

- Set the volt meter to the ohm setting, indicated by the ohm symbol.

- Connect the red lead of the volt meter to one wire of the solenoid and the black lead to the other wire.

- Observe the reading on the volt meter. A stable resistance reading indicates a good solenoid, while inconsistent readings suggest a faulty solenoid.

- Repeat the process with a known good solenoid for comparison.

- Dispose of any bad solenoids safely and avoid using them in your system.

Understanding Resistance in Solenoids

The resistance reading obtained from testing a solenoid provides valuable information about its condition. A stable resistance reading indicates that the solenoid is functioning properly. In contrast, inconsistent or erratic readings indicate a faulty solenoid that may need to be replaced. Understanding the resistance of solenoids is essential when testing them, as it helps in determining their operational state accurately.

Testing a Good Solenoid

To better understand what a stable resistance reading should look like, testing a known good solenoid is beneficial. By using a solenoid that is in proper working condition as a reference, you can compare the readings obtained from other solenoids. This allows for more accurate testing and confirms the reliability of your testing equipment.

Proper Disposal of Bad Solenoids

When testing solenoids, it's important to discard any bad ones properly. Clipping off the wires of a bad solenoid serves as a visual indicator that it is not usable. Avoid using or attempting to repair damaged solenoids, as they can cause further issues in your system. Dispose of bad solenoids following local regulations for electronic waste or recycling.

Tips for Irrigators

- Always test both solenoids when replacing one to ensure that both are in good working condition.

- Regularly perform maintenance checks on your sprinkler system to identify solenoid issues early.

- Keep spare solenoids in your truck or storage, but remember to remove and dispose of any damaged ones properly.

- Stay updated with the latest techniques and tools for testing and maintaining solenoids to improve your irrigation practices.

Conclusion

Testing solenoids using a volt meter is a simple yet effective way to determine their condition and ensure the proper functioning of your sprinkler system. By following the steps outlined in this article, you can accurately identify faulty solenoids and take appropriate action to maintain the efficiency of your irrigation system. Regular testing and maintenance will help prevent costly repairs and ensure optimal watering for your landscape.

Highlights

- Learn how to test a solenoid using a volt meter without expensive tools.

- Understand the signs that indicate a faulty solenoid.

- Discover the importance of testing solenoids for the functionality of your irrigation system.

- Follow a step-by-step guide to effectively test solenoids with a volt meter.

- Gain insights into interpreting resistance readings during solenoid testing.

- Recognize the characteristics of a good solenoid for reliable comparisons.

- Dispose of bad solenoids safely and in compliance with regulations.

- Benefit from tips and recommendations to enhance your irrigation practices.

- Ensure proper maintenance of your sprinkler system to prevent costly repairs.

- Stay up-to-date with the latest techniques and tools for solenoid testing and maintenance.

FAQ

Q: How often should I test my solenoids?

A: It is recommended to test solenoids at least once a year to ensure their proper functioning. Regular testing can help identify any issues early on and prevent further damage to the system.

Q: Can I test solenoids while they are installed in the sprinkler system?

A: Yes, you can test solenoids from the controller or directly at the solenoid location. However, it is essential to follow proper safety precautions and ensure the system is powered off before testing.

Q: What do I do if all my solenoids are showing faulty readings?

A: If all your solenoids are consistently showing faulty readings, it could indicate a problem with the volt meter or the testing technique. Double-check your equipment and procedure, or consult a professional for assistance.

Q: How can I dispose of bad solenoids responsibly?

A: It is recommended to check local regulations for electronic waste disposal or recycling centers. Many communities have specific guidelines for discarding electronic components safely.

Q: Are there any alternative methods for testing solenoids?

A: While using a volt meter is the most common and reliable method for testing solenoids, there are other specialized tools available in the market. These tools may provide additional features and insights during testing.