Unveiling the Truth About Fuel Additives: Watch the Results!

Table of Contents

- Introduction 🌟

- Understanding Modern Fuel Injection Cleaning Systems

- Changes in Cars and Gasoline Over Time

- The Impact of Ethanol in Modern Gasoline

- Carbon Build-up in Gasoline Direct Injection Systems

- The Limitations of Old-Fashioned Additives

- The Ineffectiveness of Sea Foam for Modern Cars

- The Importance of Using Additives Made for Modern Cars

- The Power of Polyethylamine (PEA)

- Introduction to PEA as a Cleaning Ingredient

- How PEA Helps Clean Carbon Build-up in Engines

- Additional Benefits of PEA in Fuel Cleaning

- Corrosion Inhibitors and Ethanol Content

- Negative Effects of Ethanol on Car Performance

- How Corrosion Inhibitors Protect Fuel Systems

- Personal Experience and Results

- Using a Borescope to Assess the Effectiveness of Cleaners

- Before and After Pictures of Engine Cleaning

- Exploring a Specific Case: Toyota Corolla Troubleshooting

- Identifying the Problem with Sluggish Acceleration

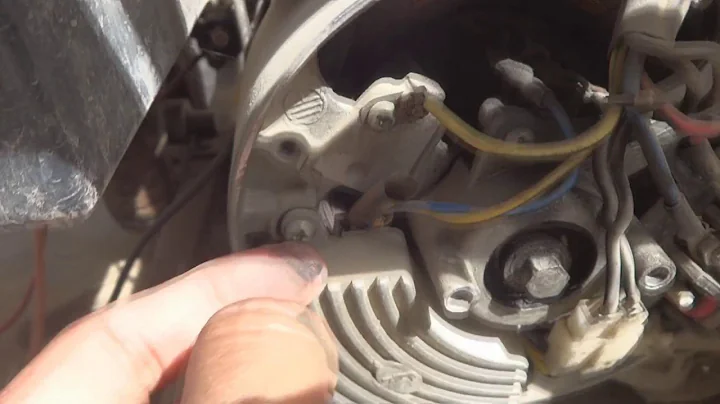

- Checking Battery and Alternator for Power Issues

- Inspecting Air Filters, Hoses, and Spark Plugs

- Examining the Engine Control Module for Failure Codes

- Analyzing Data Streams to Diagnose Fuel Trim and Airflow

- Testing the Catalytic Converter for Potential Blockage

- Considering Clogged Fuel Injectors as a Possible Cause

- The Importance of Clean Fuel Injectors

- Effects of Dirty Fuel Injectors on Engine Performance

- Using Fuel Additives to Clean and Maintain Fuel Injectors

- Conclusion 🌟

Understanding Modern Fuel Injection Cleaning Systems

The automotive industry has seen significant advancements in both vehicle technology and fuel composition over the years. This has necessitated the evolution of fuel injection cleaning systems to meet the changing demands of modern cars. In this article, we will delve into the inner workings of these systems and how they combat issues such as carbon build-up in gasoline direct injection systems. We will also discuss the limitations of old-fashioned additives and the importance of using additives specifically formulated for modern cars with ethanol-containing fuels.

The Limitations of Old-Fashioned Additives

Sea Foam: An Outdated Solution

Sea Foam, a well-known fuel additive, was originally designed for two-stroke outboard motors. However, with advancements in technology and the prevalence of four-stroke engines, including those with gasoline direct injection, Sea Foam's effectiveness has diminished. Its lack of compatibility with ethanol and modern fuel systems makes it an inadequate solution for keeping engines and fuel systems clean in today's vehicles.

Modern Cars Require Modern Solutions

To effectively clean modern engines, additives formulated specifically for modern cars and ethanol-containing fuels are necessary. One such crucial ingredient is polyethylamine (PEA), a nitrogen-based cleaner. PEA not only cleans carbon build-up commonly found in gasoline direct injection systems but also boasts corrosion inhibitors. These inhibitors are particularly valuable as they prevent ethanol and gasoline from corroding the fuel system.

Personal Experience and Results

As an experienced mechanic with over 46 years of industry knowledge, I understand the skepticism surrounding fuel additives. However, I have personally tested the efficacy of additives such as Gum Out Multi-System Cleaner using a borescope. By inspecting the engine before and after treatment, it is evident that these modern cleaning agents, with PEA as their primary cleaning ingredient, yield impressive results. Carbon build-up is significantly reduced, leading to better engine performance and longevity.

Exploring a Specific Case: Toyota Corolla Troubleshooting

Let's examine a specific case that highlights the challenges of diagnosing and resolving engine performance issues. A 2007 Toyota Corolla presented with sluggish acceleration that multiple dealers failed to diagnose correctly. The troubleshooting process involved checking various components such as battery, alternator, air filters, hoses, and spark plugs. Diagnostic tools and data analysis played a crucial role in identifying potential issues with the fuel system, including fuel trim, airflow, and oxygen sensors. Ultimately, clogged fuel injectors were suspected as the cause of the problem.

The Importance of Clean Fuel Injectors

Dirty fuel injectors can significantly impact engine performance, resulting in hesitation and poor acceleration. Regularly cleaning and maintaining fuel injectors is essential for optimal engine operation. Fuel additives, such as Royal Purple, can aid in removing deposits and ensuring proper fuel spray patterns. By addressing the cleanliness of fuel injectors, drivers can experience improved performance and fuel efficiency.

Conclusion 🌟

In conclusion, modern fuel injection cleaning systems have evolved to address the challenges posed by changes in fuel composition and engine design. Additives formulated with PEA and corrosion inhibitors are crucial for maintaining clean engines and fuel systems. Conducting thorough diagnostics, utilizing tools and data analysis, and ensuring clean fuel injectors are essential for resolving engine performance issues. By staying proactive in fuel system maintenance, drivers can prolong the life of their vehicles and enjoy optimal performance on the road.